Technology Physical Configuration

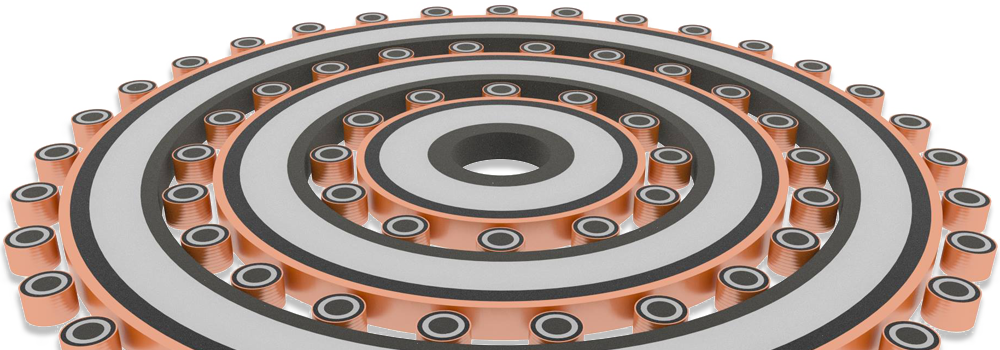

The SEG consists of three Stator Rings composed of four distinctively different materials concentrically layered to each other and fixed to a base. Surrounding each of the Plates are rotors (called Rollers) constructed with the same materials but are free to rotate around the Stator Ring. The innermost Stator Ring has 12 rollers, 22 on the second stage and 32 on the final Stator Ring. Conventional electromagnets surround the outermost set of Rollers. They are C-shaped cores and tap energy out of the rapidly orbiting Rollers by way of magnetic induction. These inductive pickup coils are connected in various configurations to supply AC or DC power at various desired voltage and current levels to suit residential, business, or industrial applications.

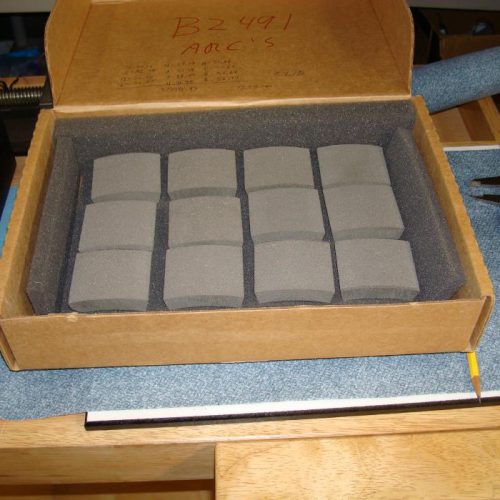

The SEG is a device constructed of 2,124 parts that make up 3 Stator rings (12 parts) and 66 Roller sets (2112). Each roller set consists of 8 segments constructed from 32 parts. Each set of Stator Rings and Rollers is configured to power out in series from the innermost to the outside, and each has ratings based on its mass or weight. The rule of thumb is 90 watts per pound or 200 watts per kilogram of the generator’s weight. It follows that the first stage or innermost is rated at 2.5kW, the second stage at 4.5kW, and the outermost rates at 8kW for a 15kW SEG unit. Therefore, the smallest unit is the innermost and is suitable for the smallest power requirements.

SEG Material Layers

The SEG is ideal for mass production, consisting of material layers in the form of simple rings for both the Stator Rings and Rollers (rotors) structures. Therefore, the SEG will cost less to manufacture than conventional electrical generators of the same power rating.

The SEG is made of four materials in layers, and each has functions to form reaction components, all working with sophisticated electromagnetic interactions in dynamic relative motion.

-

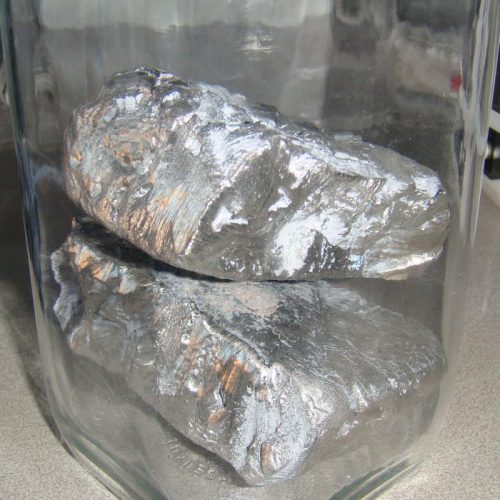

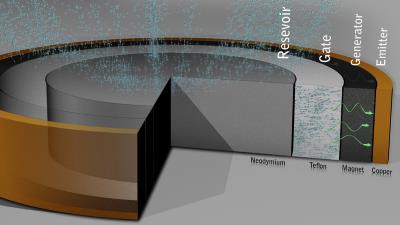

Innermost Layer

The innermost layer has the rare earth element Neodymium. It functions as the “reservoir” of electrons from which the generator will draw electrons to form electron pairs (bosons). The element Nd60 has an essential electron capture effect that brings in electrons from the outside atmosphere, which completes the electrical circuit and an open system energy cycle.

-

Dielectric Layer

Outwardly next is a dielectric layer. The layer regulates the flow of paired charges, otherwise, it would behave unregulated, like a reservoir without a dam. This layer is a Teflon material for its negative charge properties and high density. It is a barrier to fermions or single electrons but amiable to composite electrons, which are Bosons with the characteristics of a photon.

-

Magnetic Layer

Next is the most critical layer and the main focus of research and development, the magnetic layer. The unique magnetization process programs the permanent magnetic layer with wave patterns. It is a trade secret that cannot be reverse-engineered.

-

Emitter Layer

The outermost is the conductive band or “emitter” layer, consisting of (OFHC) copper. It makes it possible for the Rollers to spin and orbit around the Stator Ring on a magnetic bearing. This means the generator’s moving parts can never wear out, and thus it can last easily for decades. This is the final layer where high-speed charges are emitted from the surfaces of the copper, driving the rollers and resulting in a halo of negatively charged air around it.

Proof-of-Concept – SEG Electromechanical Functions

The SEG research and development has resulted in four primary demonstrations

unit as proof-of-concept:

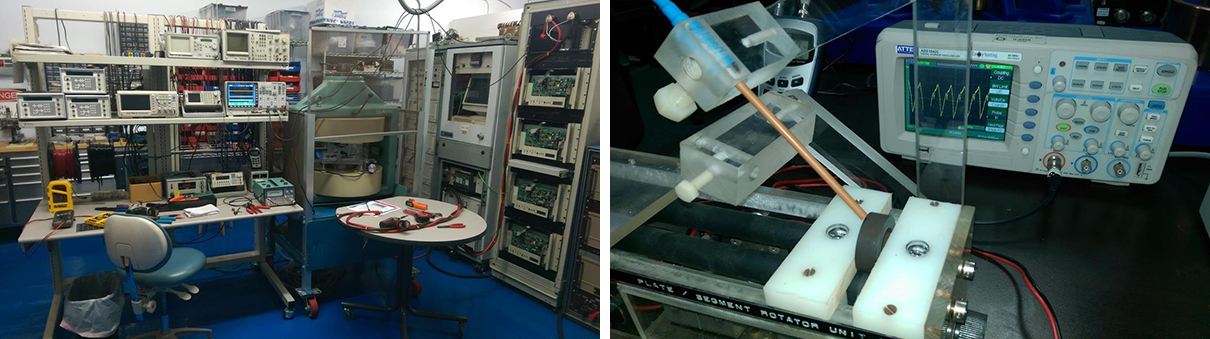

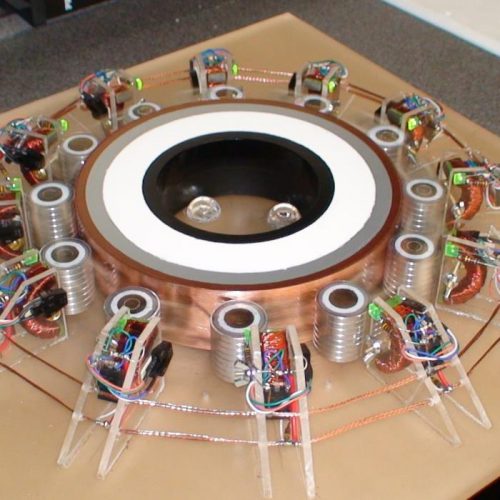

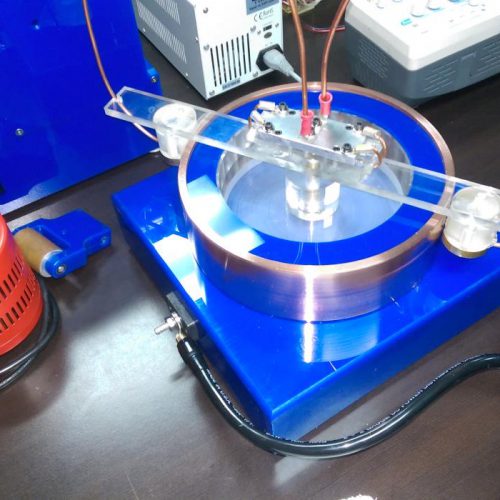

Upper Left

Upper left, the SEG mockup demonstrates the innermost set of Stator Ring and Rollers arranged by a general magnetic field. This motor design confirms electromechanically how rollers can spin and orbit around the stator on a magnetic track over the copper band or ring.

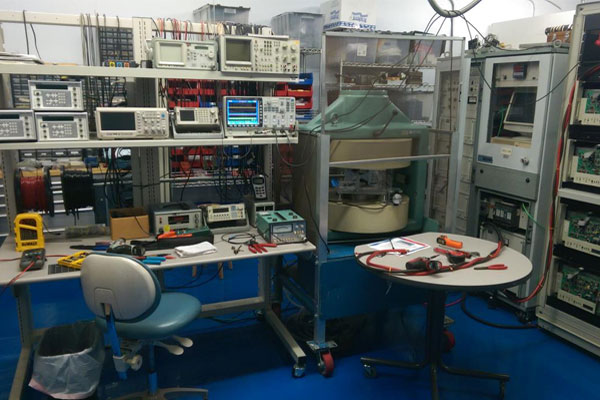

Upper Right

The upper right confirms the SEG will operate as a unipolar motor and provides evidence that rollers are set into motion by radial electrical output or currents from the Stator Ring.

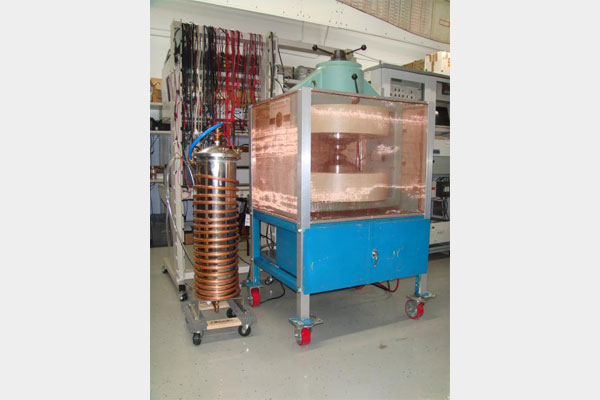

Lower Left

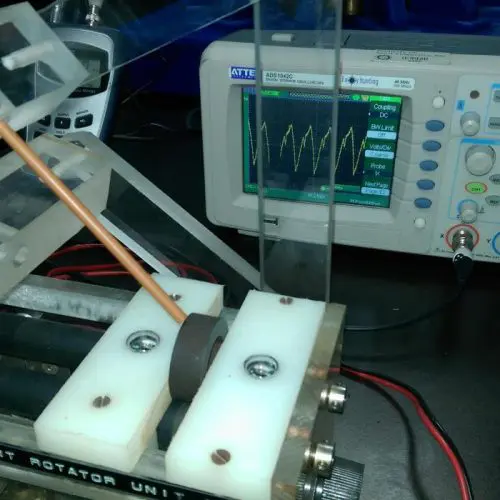

Lower left is the testing platform for magnetic waveforms consisting of a custom gauss meter scanning assembly, where the results are displayed by the digital oscilloscope. The magnetic layer will be impressed with a proprietary process of magnetization developed only at the SEG laboratory.

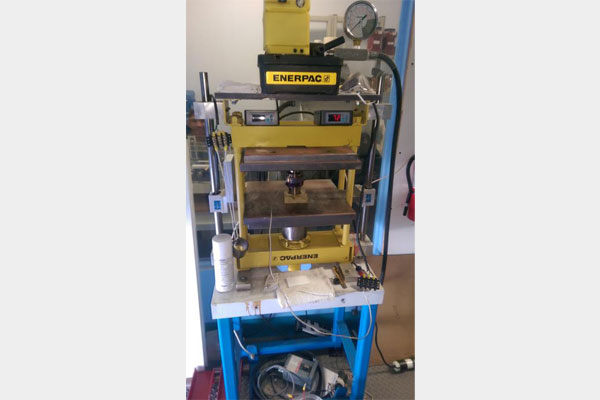

Lower Right

The lower right confirms and isolates the magnetic bearing effect inherent in the SEG design. Proving that all rollers are magnetically suspended, therefore no friction or wear between parts (stator and rotors).

Proof-of-Concept – SEG Electromechanical Functions

The SEG research and development has resulted in four primary demonstrations unit as proof-of-concept:

Upper Left

Upper left, the SEG mockup demonstrates the innermost set of Stator Ring and Rollers arranged by a general magnetic field. This motor design confirms electromechanically how rollers can spin and orbit around the stator on a magnetic track over the copper band or ring.

Upper Right

Upper right, confirming the SEG will operate as a unipolar motor and provides the evidence that rollers are set into motion by radial electrical output or currents from the Stator Ring.

Lower Left

Lower left is the testing platform for magnetic waveforms consisting of a custom gauss meter scanning assembly, where the results are displayed by the digital oscilloscope. It is the magnetic layer that is will be impressed with a proprietary process of magnetization developing only at the SEG laboratory.

Lower Right

Lower right, confirms and isolated the magnetic bearing effect is inherent in the SEG design. Proving that all rollers are magnetically suspended, therefore no friction or wear between parts (stator and rotors).

Proof-of-Concept – SEG Electromechanical Functions

The SEG research and development has resulted in four primary demonstrations unit as proof-of-concept:

Upper Left

Upper left, the SEG mockup demonstrates the innermost set of Stator Ring and Rollers arranged by a general magnetic field. This motor design confirms electromechanically how rollers can spin and orbit around the stator on a magnetic track over the copper band or ring.

Upper Right

Upper right, confirming the SEG will operate as a unipolar motor and provides the evidence that rollers are set into motion by radial electrical output or currents from the Stator Ring.

Lower Right

Lower right, confirms and isolated the magnetic bearing effect is inherent in the SEG design. Proving that all rollers are magnetically suspended, therefore no friction or wear between parts (stator and rotors).

Lower Left

Lower left is the testing platform for magnetic waveforms consisting of a custom gauss meter scanning assembly, where the results are displayed by the digital oscilloscope. It is the magnetic layer that is will be impressed with a proprietary process of magnetization developing only at the SEG laboratory.

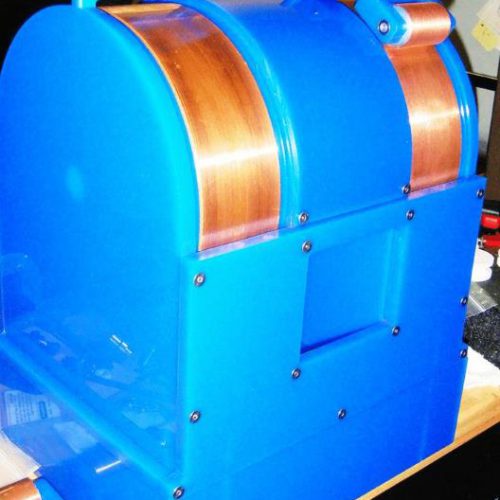

SEG Magnetization Laboratory

The SEG magnetization process is a trade secret that cannot be reverse-engineered, and that know-how is proprietary. SEGM has developed a laboratory with the equipment required to investigate SEG magnetic requirements. Once stator rings and rotor rollers are magnetized correctly with matching waveforms, they will mesh together like a planetary gear, in magnetic terms, enabling it to function as an open-system electrical generator.